Installers of floors need work boots that are both comfortable and protect their feet. Because they have to move around all the time, stand for long periods, and move heavy tools and materials, they need good work boots for their safety and health.

If you’re in the market for a new pair of work boots and you’re a flooring installer, you might be wondering what the best work boots for flooring installers are.

In this review, I’ll talk about some of the best work boots for floor installers on the market right now. I will look at things like comfort, durability, resistance to slipping, and other essential things for people who install floors.

This review will help you choose the best work boots for your needs, whether you are a professional installer or just like to do things yourself.

Contents

Understanding The Importance Of Proper Footwear In The Flooring Industry

Best work boots for flooring installers: understanding the importance of proper footwear in the flooring industry

As a flooring installer, your job requires you to be on your feet for long hours in potentially dangerous work environments. This is why having the proper work boots is essential. In this blog post, we will explore the safety hazards of incorrect footwear and the benefits of using work boots designed for flooring installation.

Safety Hazards Of Incorrect Footwear

Wearing incorrect footwear can result in a variety of safety hazards in the work environment. Some of these hazards include:

- Slipping on a wet or slick surface, leading to falls and potential injury.

- Foot fatigue that can result in discomfort, pain, and long-term injuries such as plantar fasciitis or knee problems.

- Stepping on sharp objects or materials that could cause puncture wounds and injuries.

- Being exposed to toxic chemicals and contaminants without proper protection, potentially leading to skin or health problems.

Benefits Of Using Work Boots Designed For Flooring Installation

Investing in a good pair of work boots designed for flooring installers can provide numerous benefits such as:

- Superior grip and slip-resistant soles that can help prevent slips and falls.

- Proper arch support and cushioning inside the boots that can help reduce fatigue, discomfort, and pain.

- Steel-toe or composite-toe protection that can help prevent puncture wounds and crush injuries.

- Electrical hazard protection that can help prevent electric shock and injuries.

- Waterproof and chemical-resistant materials that can provide protection and keep feet dry even in hazardous environments.

Proper footwear is crucial for flooring installers to ensure their safety and well-being while on the job. Investing in work boots designed for flooring installation can have a significant impact on injury prevention and overall comfort and job satisfaction.

Considerations When Choosing Work Boots For Flooring Installers

Best work boots for flooring installers – considerations when choosing work boots for flooring installers

As a flooring installer, choosing the right work boots is critical to ensuring you stay safe, comfortable and fully supported throughout the day. The right boots can make all the difference in preventing injuries, increasing productivity, and providing the necessary protection you need.

To help you choose the best work boots for your needs, consider the following:

Material Quality

Material quality is crucial when selecting work boots for flooring installers. Look for boots made of durable, high-quality materials that can withstand the tough demands of your job. Leather and synthetic materials are popular choices for work boots, as they are tough and long-lasting.

Additionally, check for features such as waterproofing and breathability to ensure your feet stay dry and comfortable.

Comfort And Support

The comfort and support provided by work boots are essential to prevent fatigue and injury throughout the day. Look for features such as cushioned insoles, padded collars, and midsoles that offer adequate shock absorption. Additionally, check for proper arch support and ample toe room to prevent foot discomfort and other common issues.

Slip-Resistance And Traction

As a flooring installer, you’ll likely work on a variety of surfaces, so slip-resistance and traction are crucial features to look for in work boots. Slip-resistant soles with deep treads can help prevent slips and falls on wet, slippery or uneven surfaces.

Look for boots with a high traction rating and consider the type of sole material, as softer compounds tend to provide better grip.

Protective Features

Flooring installers work with heavy machinery and sharp tools that can pose a safety risk. Look for work boots that offer adequate protection, such as reinforced steel toes, puncture-resistant plates, and electrical hazard protection. These protective features can help prevent serious injuries on the job.

Proper Fit And Sizing

Finally, choosing the right size and fit is essential to ensure optimal comfort and safety. Take the time to measure your feet and try on boots in-store before you buy them. Be sure to wear the same type of socks you wear on the job and walk around in the boots for several minutes to ensure a good fit.

Remember, poorly fitting boots can cause foot problems and even lead to workplace injuries.

By considering these factors when selecting work boots for flooring installers, you can find a pair that meets your unique needs and provides the necessary protection, comfort, and support for a long day on the job.

Top Features Of The Best Work Boots For Flooring Installers

When it comes to flooring installers, their work boots need to be sturdy and durable. Wearing comfortable and safe boots is crucial for staying productive and avoiding injuries. In this post, we’ll explore the essential features that the best work boots for flooring installers must have.

Impact Resistance Steel Toes

Flooring installers are frequently exposed to heavy objects falling on their feet, leading to serious injuries. That’s why work boots with steel toes are required for providing reliable protection. Moreover, the steel toe boots need to be impact-resistant, capable of withstanding the weight of objects with great force.

- Steel toes must be rated to withstand a minimum weight of 75 pounds dropped from a height of 3 meters.

- The steel cap should cover the toes fully and not affect the overall comfort.

Electrical Hazard Protection

Flooring installers work with electric saws and wiring systems, and they need protection against electrocution. Therefore, their work boots should include electrical hazard standards.

- Work boots with an electrical hazard rating must prevent electric current from passing through the sole.

- The rating must indicate the maximum electrical charge the boots’ sole can withstand, up to 14,000 volts.

Waterproof Materials

Flooring installers work in various indoor and outdoor environments, exposing their boots to water and other liquids. Their work boots must have waterproof materials to ensure they stay dry, comfortable, and healthy.

- Work boots made from leather or synthetic materials treated with a waterproof coating repel water effectively.

- Some work boots come with a breathable, water-resistant membrane that enhances the boots’ comfort and helps protect the feet from water and moisture.

Cushioning Support

Flooring installers experience extended periods of standing, kneeling, and bending, which puts a strain on their feet, ankles, and joints. Therefore, their work boots need extra cushioning support for comfort and shock absorption.

- Work boots with cushioned insoles and midsoles help reduce the risk of muscle fatigue and feet injuries.

- Soft and comfortable boots that fit well to the feet offer better support and ease the pressure on the balls and heels of the feet.

Anti-Fatigue Footbeds

Anti-fatigue footbeds improve the circulation of blood around the feet and minimise foot fatigue.

- This type of work boot is sturdy and robust to sustain prolonged periods of work.

- Anti-fatigue footbeds help transfer weight from the balls of your feet to the proper heel and toe area for better support.

Lightweight Designs

Flooring installers work in agile environments that require them to move quickly and efficiently, often on hard surfaces. Consequently, they need work boots that are lightweight and flexible enough to move with ease.

- Lightweight work boots reduce muscle fatigue and allow users to move faster and more efficiently.

- The perfect combination of a robust design with lightweight materials provides flooring installers with top-of-the-line work boots that meet all their needs.

By considering these features and selecting the right work boots, the job will become more comfortable, efficient, and safe for flooring installers. Stay safe out there!

Check Out Our Best Work Boots For Flooring Installers

When you’re on your feet all day, comfort is key. The wrong pair of work boots can leave you with sore feet, aching legs, and even back pain. If you’re a flooring installer, you need a boot that will provide all-day comfort while still being durable enough to stand up to the rigors of the job.

Here are our picks for the Best Work Boots For Flooring Installers::

1. Keen Utility Men’s Pittsburgh Steel Toe Work Boot

This boot from Keen Utility is built for comfort, with a cushioned insole and a roomy toe box. The steel toe protects your feet from dropped objects, and the waterproof leather upper will keep your feet dry in wet conditions.

Key Features:

- The shoe is made of 100 pieces of fabric and has a rubber sole.

- The shaft is about 6 inches from the arch, and the heel is also about 6 inches.

- The opening of the boot is about 12 inches around.

- Asymmetrical steel toes on the left and right make the toe box bigger and provide more comfort.

- With KEEN, you can stay dry. DRY membrane liner and a mesh liner built in

- Outsoles are made of non-marking, oil- and slip-resistant rubber with lug patterns for better grip.

- Electrical Hazard (EH)-rated to protect from live electrical circuits

KEEN. Full-length stability plate from Key-Tech for extra support - Moisture-wicking materials and PU insoles can be taken out for more comfort.

- 90° heel for extra stability and “locking in” of the foot.

Benefits:

- The asymmetrical shape of the steel toe gives the wearer a more comfortable and unobtrusive fit.

- The waterproof membrane and mesh liner work together to keep feet dry and comfortable in wet places.

- The outsoles are made of oil- and slip-resistant rubber with lugs that give you a good grip even on wet surfaces.

- The electrical hazard (EH) rating gives people who work near live electrical circuits an extra layer of safety.

- The full-length KEEN KEY-TECH stability plate supports the foot and helps spread weight evenly.

- Moisture-wicking fabrics and PU insoles that can be removed add to the shoes’ comfort.

Drawbacks:

- The 90-degree heel may not be suitable for all jobs since walking on uneven surfaces in them can be hard.

- People with wider feet might not be able to wear the boot because the steel toe might not leave enough room for comfort.

Overall, the Keen Utility Men’s Pittsburgh Steel Toe Work Boot is a good choice for people needing a strong and safe shoe. Its features and benefits are more critical than its flaws, which makes it a good investment for people who need a good work boot.

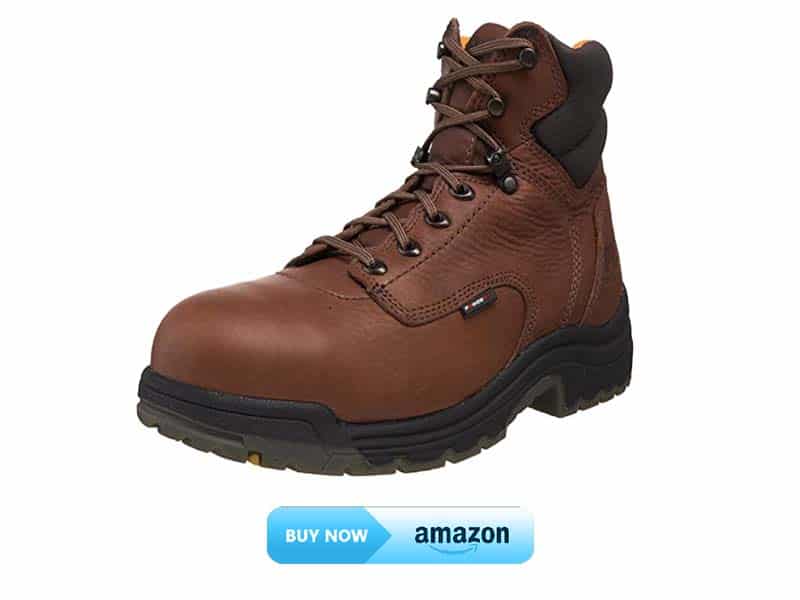

2. Timberland PRO Men’s Titan 6″ Safety-Toe Work Boot

Timberland PRO’s Titan work boot is another great option for flooring installers. It has a cushioned insole, and a padded collar for comfort, and the steel toe protects your feet from hazards. The boot is also slip-resistant, which is essential when you’re working with slippery materials.

Key Features

- Made from 100% leather, which is strong and resistant to water.

- Imported, which means that the materials and construction are of high quality.

- The sole is made of synthetic materials, making it more durable and grippier.

- The shaft is about 6 inches long “from the arch, giving your ankles plenty of support.

- The heel is about 1.75 inches tall “, giving the foot a place to rest that is comfortable and stable.

- The opening of the boot measures about 10.5 “, so it’s easy to put on and take off.

- Made from high-quality full-grain leather, it looks stylish and professional.

- The upper is safe and follows workplace rules because it has no metal or holes.

- Features a nylon diffusion shank for structural support and torsional rigidity, which helps reduce foot fatigue.

Benefits:

- These shoes are designed for people who work in tough environments and provide all-day comfort, durability, and protection.

- These boots are made to last because they are made of high-quality materials and are put together well.

- The leather is water-resistant, and the sole is made of a material that doesn’t stick to wet or slippery surfaces.

- The upper has no metal or mutilations, so it complies with workplace rules and still looks stylish.

- The nylon diffusion shank helps keep your feet from getting tired, so these boots are a good choice for people who spend a lot of time on their feet.

Drawbacks:

- These boots are more expensive than other work boot options, but they are of high quality and will last a long time.

- The 6 “Some people may not get enough ankle support from the shaft, depending on the needs of their jobs.

3. Caterpillar Men’s Steel Toe Work Boot

This boot from Caterpillar is built for durability, with a tough leather upper and a steel toe that meets ASTM safety standards. It also has a cushioned insole for comfort, and the slip-resistant sole will keep you safe on the job.

Key Features

- Made from 100% leather, which is strong and protects you from workplace hazards.

- Imported, which means that the materials and construction are of high quality.

- The synthetic sole makes the shoe last longer and grip the ground better.

- The shaft is about 6″ from the arch, which gives your ankles plenty of support.

- The heel is about 1.25 inches tall, giving the foot a comfortable and stable resting place.

- The platform is about 0.75 inches high, giving you more height and stability.

- The boot’s opening is about 10.5″ all the way around, making it easy to put on and take off.

- The cushioned, breathable Climasphere insole will keep your feet comfortable all day at work.

- Goodyear Welt Construction makes shoes as durable as possible and lets them be flexible.

- Made with high-quality, oiled full-grain leather or nubuck to last and protect for a long time.

- Slip-resistant soles help you keep your footing on surfaces with less grip.

- Electrical Hazard (EH) protects against open circuits up to 600 volts when the weather is dry (ASTM F2413-18).

Benefits:

- These shoes are designed for people who work in tough environments and provide all-day comfort, durability, and protection.

- These boots are made to last because they are made of high-quality materials and are put together well.

- The cushioned, breathable Climasphere insole helps keep feet comfortable all day at work, reducing fatigue and pain.

- Goodyear Welt Construction makes these boots as durable and flexible as possible, making them a good choice for even the hardest jobs.

- The slip-resistant outsole gives you a good grip on surfaces with less grip, making it less likely that you will slip and fall.

- Electrical Hazard (EH) protection gives people who work with electricity more safety.

Drawbacks:

- Some people may not get enough ankle support from the 6″ shaft, depending on the needs of their jobs.

- Even though the leather is strong and protects you from hazards at work, it may take a while to break in and become comfortable.

Quick Comparative Table For Better Understand

| Brand and Model | Keen Utility Men’s Pittsburgh Steel Toe Work Boot | Timberland PRO Men’s Titan 6″ Safety-Toe Work Boot | Caterpillar Men’s Steel Toe Work Boot |

|---|---|---|---|

| Toe Protection | Steel Toe | Alloy Safety Toe | Steel Toe |

| Comfort | Removable dual-density EVA footbed, breathable membrane, and padded collar and tongue | Polyurethane midsole for cushioning, antimicrobial footbed, and padded collar | Climasphere breathable insole, cushioned EVA midsole, and padded collar |

| Sole | Slip-resistant rubber outsole with tread pattern for traction | Rubber outsole with slip-resistant tread pattern | Rubber outsole with slip-resistant tread pattern |

| Material | waterproof and breathable membrane, and oil- and slip-resistant rubber outsole | Full-grain leather upper, nylon shank for structural support, and rubber outsole | Full-grain leather upper, nylon mesh lining, and rubber outsole |

| Additional Features | Electrical hazard protection | Electrical hazard protection and lightweight design | Electrical hazard protection |

How To Take Care And Maintain Work Boots For Flooring Installers

- Clean your boots regularly using a brush or damp cloth

- Dry your boots properly after getting wet to prevent mold and odor

- Apply a waterproofing spray to protect your boots from water damage

- Use a leather conditioner to prevent cracking and maintain the suppleness of leather

- Store your boots in a dry and cool place to prevent damage from heat and humidity

- Replace worn-out insoles regularly to maintain comfort and support

- Replace worn-out boots when they no longer provide adequate protection and support

FAQ

What should I look for in work boots as a flooring installer?

As a floor installer, you should look for work boots that don’t slip, have good support for your arches, and fit well. Also, if your job requires it, consider getting boots with a protective toe and protection from electrical hazards.

Are steel toe boots necessary for flooring installers?

Floor installers don’t always need steel-toed boots, but they can add an extra layer of protection in case something heavy falls on their toes. If your job requires you to move heavy equipment or lift heavy things, steel-toed boots could be a good choice for you.

How much should I expect to spend on work boots for flooring installers?

The price of work boots for people who put in floors ranges from about $50 to $200 or more. When choosing a pair of work boots, you should consider your budget and the most important features, such as non-slip and comfort.

How often should I replace my work boots as a flooring installer?

Work boots should be replaced when they no longer support, protect, or make you feel comfortable enough. Installers of floors should replace their work boots every 6 to 12 months, depending on how much wear and tear they get.

Final words

Ultimately, floor installers need good work boots to ensure safety, comfort, and health. The Best Work Boots For Flooring Installers should be comfortable and supportive, last long, and have soles that don’t slip. Other important things to consider are protection for your toes, protection from electrical hazards, waterproofing, and insulation.

Based on our review, Timberland, Keen Utility, and Caterpillar are some of the best brands for flooring installers looking for work boots. These boots are very comfortable, durable, and won’t slip. They also have extra features like protection from electrical hazards and waterproofing.

When buying work boots, you must consider your specific needs and preferences, like the type of flooring you work on and the environment you work in. Flooring installers can do their jobs well and stay safe on the job site if they have the right work boots.